Creating the best products for everyone

New Product Development Quality Control

——

New product design review

Confirmation of customers' requirem-

ents,product and design and other Info.

Incoming Quality Control

IQC tests the raw materials.

Tests for the design

Verify the product design and the

reliability and rationality of the raw

materials.

Low-volume Production

Verify product quality stability and all

process documents and equipment. Further calibrate and review design drawings.

Outgoing Quality Control

Final products shall be inspected as per

relevant standards and specifications before storage and shipment.

Mass Production

Mass production starts after the gold

sample is confirmed.

Customer sample confirmation

Provide customers with verified product to confirm the final sample.

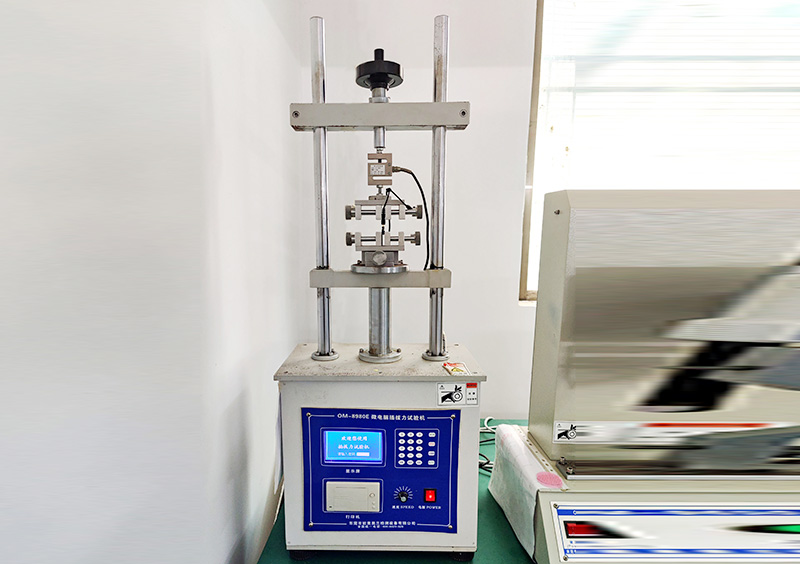

Test Equipment

We have professional testing and inspection facilities, 80% tested in our factory

Quality Control

Quality control is strictly implemented in accordance with ISO standards. From supplier selection and review to IQC for raw material testing, IPQC process control, QA finished product inspection, OQC shipment control.

Quality Objective:

Qualified rate of shipment≥99.6%

On time delivery≥99%

Customer Complaints≤2/year

AQL Standards:

CRI→ 0

MAJ→ 0.65

MIN→ 1

All the products are

fully inspected.

Execution standard of

on-site management:

ISO 9001 2015

Execution standard of

on-site quality control:

MIL-STD-105E

Supply System

We have developed a professional supply chain system.

Environmental protection certification guide for material purchasing:

Based on the laws and regulations of diverse countries in the world, especially EU WEEE and RoHS directives, Maier has developed a guide that is suitable for the purchase of conpenents and parts with reference to industry standard for the requirements of environmental protection and combining with Maier's actual formulation. Meanwhile, the contents of the guide may be revised in accordance with EU WEEE and ROHS directives, laws and regulations of various regions in the world and with reference to the changes of the industry standards.

Select Suppliers

Choose superior suppliers

Manage Suppliers

Lowliest place elimination series is carried out to the suppliers with monthly and annual comparison.

Screen out Suppliers

Timely select the suppliers through the

management.

Inspection System

Test the product with professional facilities and responsible attitude.

IQC

store the

incoming

materials

product

assembling

storage and

inspection for

finished product

OQC

Shipping

100% sampling the incoming materials before storage

storage after the

qualified random

inspection

strictly refer to SOP,

along with patrol

management carried

out by IPQC and FQC

test product according

to finished product

inspection standards

(reliability testing

included)

actively cooperate

with customers or

third party inspection company to inspect the goods on site

100% ship on time

Professional production

management standard

In accordance with ISO 9001

Rigorous pre-service training

Each employee has a 7-day trial

period and a one-month probation period

58% of the old employees

retention rate

Old employees work more efficiently and are more familiar with the products

Incentive system for senior

employees

Employees will receive a bonus

for each full year of service

Production Management System

In accordance with ISO 9001:2015, standard quality management system.

All the materials are RoHS compliant.

-

Salt-Spray-Test

Salt-Spray-Test -

Salt-Spray-Test

Salt-Spray-Test -

Salt-Spray-Test

Salt-Spray-Test -

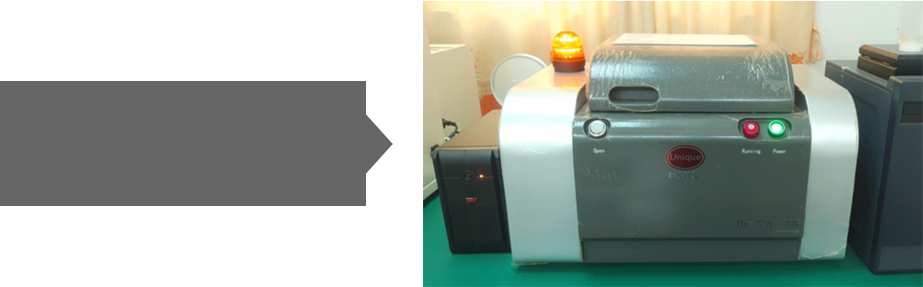

RF-Test-(iODM)

RF-Test-(iODM) -

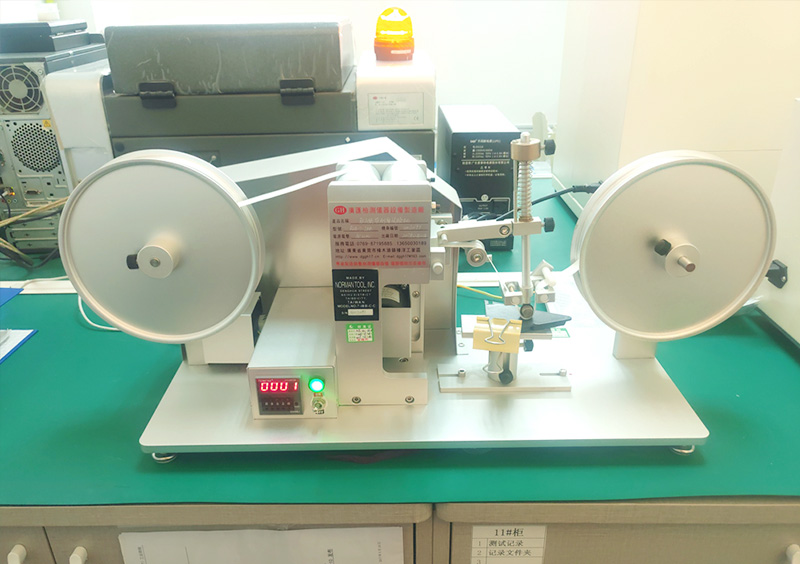

RCA-Test

RCA-Test -

Pull-Test

Pull-Test -

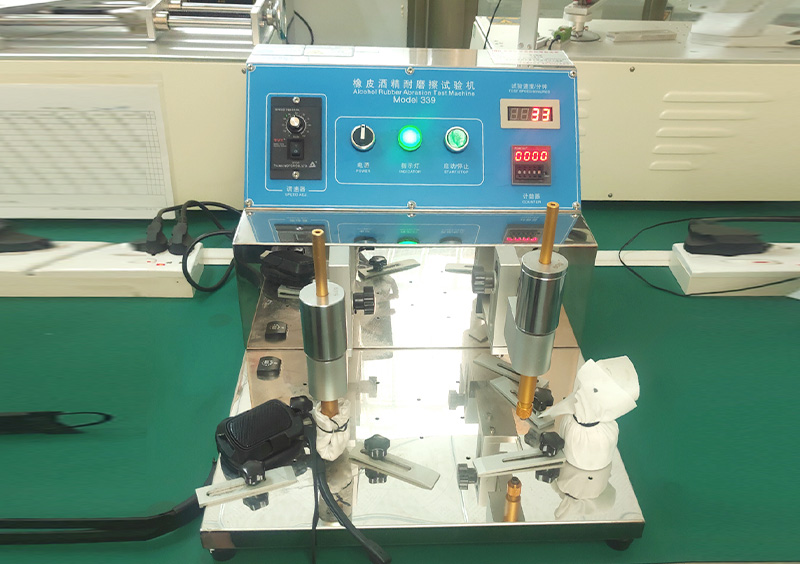

Printing-Test

Printing-Test -

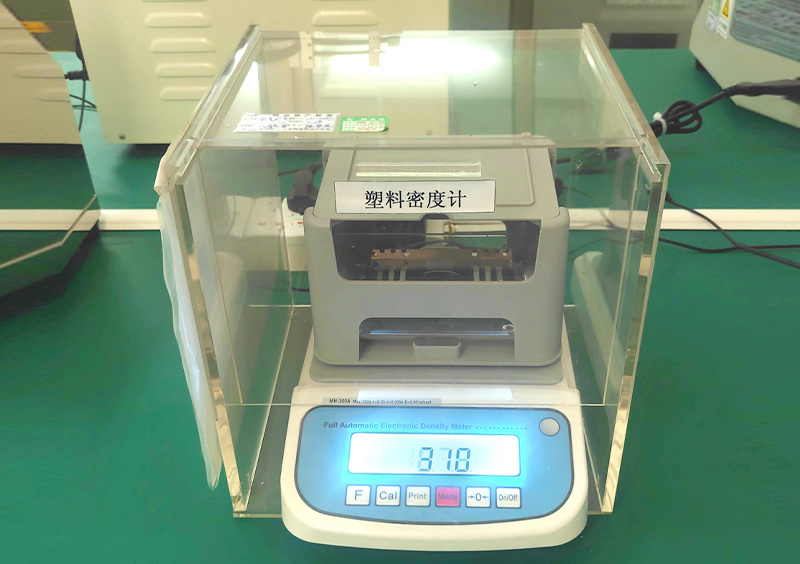

Plastic-Density-Test

Plastic-Density-Test

Home Page

Previous Page

1

2

3

Next Page

Last Page

CONTACT ONTA

Address:

No.9, NanSan Rd, Laohuling Vil, Xiaojinkou Town, Huizhou

Tel:

86-0752-2782266

Navigation

Contact way

E-mail:steven@hzmaier.com

Fax:86-752-2783118

Phone:0752-2782266 2782299

All rights reserved: Maier Electronics Co., Ltd. ICP: 12018864